ADAC Headquarters

Munich

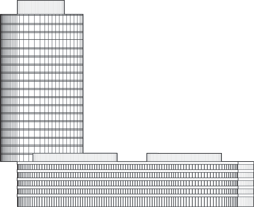

- CTBUH Drawing

- Facts

-

Metrics

You must be a CTBUH Member to view this resource.

To Tip:

Height is measured from the level of the lowest, significant, open-air, pedestrian entrance to the highest point of the building, irrespective of material or function of the highest element (i.e., including antennae, flagpoles, signage and other functional-technical equipment).Architectural:

Height is measured from the level of the lowest, significant, open-air, pedestrian entrance to the architectural top of the building, including spires, but not including antennae, signage, flag poles or other functional-technical equipment. This measurement is the most widely utilized and is employed to define the Council on Tall Buildings and Urban Habitat (CTBUH) rankings of the "World's Tallest Buildings."Occupied:

Height is measured from the level of the lowest, significant, open-air, pedestrian entrance to the highest occupied floor within the building.Above Ground

The number of floors above ground should include the ground floor level and be the number of main floors above ground, including any significant mezzanine floors and major mechanical plant floors. Mechanical mezzanines should not be included if they have a significantly smaller floor area than the major floors below. Similarly, mechanical penthouses or plant rooms protruding above the general roof area should not be counted. Note: CTBUH floor counts may differ from published accounts, as it is common in some regions of the world for certain floor levels not to be included (e.g., the level 4, 14, 24, etc. in Hong Kong).Below Ground

The number of floors below ground should include all major floors located below the ground floor level.

Official Name

ADAC Headquarters

Other Names

ADAC Zentral Neubau

Type

Building

Status

Completed

Completion

2012

Country

City

Address

Function

A mixed-use tall building contains two or more functions (or uses), where each of the functions occupy a significant proportion of the tower's total space. Support areas such as car parks and mechanical plant space do not constitute mixed-use functions. Functions are denoted on CTBUH "Tallest Building" lists in descending order, e.g., "hotel/office" indicates hotel function above office function.

Office

Structural Material

Both the main vertical/lateral structural elements and the floor spanning systems are constructed from steel. Note that a building of steel construction with a floor system of concrete planks or concrete slab on top of steel beams is still considered an “all-steel” structure as the concrete elements are not acting as the primary structure.

All-Concrete

Both the main vertical/lateral structural elements and the floor spanning systems are constructed from concrete which has been cast in place and utilizes steel reinforcement bars and/or steel reinforced concrete which has been precast as individual components and assembled together on-site.

All-Timber

Both the main vertical/lateral structural elements and the floor spanning systems are constructed from timber. An all-timber structure may include the use of localized non-timber connections between timber elements. Note that a building of timber construction with a floor system of concrete planks or concrete slab on top of timber beams is still considered an “all-timber” structure as the concrete elements are not acting as the primary structure.

Mixed-Structure

Utilizes distinct systems (e.g. all-steel, all-concrete, all-timber), one on top of the other. For example, a Steel Over Concrete indicates an all-steel structural system located on top of an all-concrete structural system, with the opposite true of Concrete Over Steel.

Composite

A combination of materials (e.g. steel, concrete, timber) are used together in the main structural elements. Examples include buildings which utilize: steel columns with a floor system of reinforced concrete beams; a steel frame system with a concrete core; concrete-encased steel columns; concrete-filled steel tubes; etc. Where known, the CTBUH database breaks out the materials used within a composite building’s primary structural elements.

Composite

Height

93 m / 305 ft

Floors Above Ground

23

Floors Below Ground

3

Tower GFA

125,000 m² / 1,345,489 ft²

Rankings

-

By function

You must be a CTBUH Member to view this resource.

-

By material

You must be a CTBUH Member to view this resource.

Construction Schedule

Proposed

Construction Start

Completed

Architect

Usually involved in the front end design, with a "typical" condition being that of a leadership role through either Schematic Design or Design Development, and then a monitoring role through the CD and CA phases.

Structural Engineer

The Design Engineer is usually involved in the front end design, typically taking the leadership role in the Schematic Design and Design Development, and then a monitoring role through the CD and CA phases.

Other Consultant

Other Consultant refers to other organizations which provided significant consultation services for a building project (e.g. wind consultants, environmental consultants, fire and life safety consultants, etc).

Other Consultant refers to other organizations which provided significant consultation services for a building project (e.g. wind consultants, environmental consultants, fire and life safety consultants, etc).

These are firms that consult on the design of a building's façade. May often be referred to as "Cladding," "Envelope," "Exterior Wall," or "Curtain Wall" Consultant, however, for consistency CTBUH uses the term "Façade Consultant" exclusively.

Material Supplier

Material Supplier refers to organizations which supplied significant systems/materials for a building project (e.g. elevator suppliers, facade suppliers, etc).

Material Supplier refers to organizations which supplied significant systems/materials for a building project (e.g. elevator suppliers, facade suppliers, etc).

You must be a CTBUH Member to view this resource.

Owner

ADAC

Architect

Usually involved in the front end design, with a "typical" condition being that of a leadership role through either Schematic Design or Design Development, and then a monitoring role through the CD and CA phases.

Structural Engineer

The Design Engineer is usually involved in the front end design, typically taking the leadership role in the Schematic Design and Design Development, and then a monitoring role through the CD and CA phases.

The Peer Review Engineer traditionally comments on the information produced by another party, and to render second opinions, but not to initiate what the design looks like from the start.

Henke + Rapolder Ingenieurgesellschaft

MEP Engineer

The Design Engineer is usually involved in the front end design, typically taking the leadership role in the Schematic Design and Design Development, and then a monitoring role through the CD and CA phases.

NEK Beratende Ingenieure

Contractor

The main contractor is the supervisory contractor of all construction work on a project, management of sub-contractors and vendors, etc. May be referred to as "Construction Manager," however, for consistency CTBUH uses the term "Main Contractor" exclusively.

ARGE Neubau ADAC Zentrale

Other Consultant

Other Consultant refers to other organizations which provided significant consultation services for a building project (e.g. wind consultants, environmental consultants, fire and life safety consultants, etc).

Other Consultant refers to other organizations which provided significant consultation services for a building project (e.g. wind consultants, environmental consultants, fire and life safety consultants, etc).

These are firms that consult on the design of a building's façade. May often be referred to as "Cladding," "Envelope," "Exterior Wall," or "Curtain Wall" Consultant, however, for consistency CTBUH uses the term "Façade Consultant" exclusively.

Material Supplier

Material Supplier refers to organizations which supplied significant systems/materials for a building project (e.g. elevator suppliers, facade suppliers, etc).

Material Supplier refers to organizations which supplied significant systems/materials for a building project (e.g. elevator suppliers, facade suppliers, etc).

CTBUH Awards & Distinctions

Best Tall Building, by Region, Europe 2013 Award of Excellence

2013 CTBUH Awards

Videos

11 June 2013 | Munich

Beyond Green – Engineering High-Rises for Sustainable Cities

High-rise buildings make an important contribution in the design of sustainable cities – provided they are planned accordingly and with a holistic perspective. In this...

Research

11 June 2013

The Special Nature of the European Skyscraper

Viewpoints: The London Conference

European architecture is at a crossroads. Its commercial and environmental realities are driving buildings ever-higher, but not all are convinced. In this article – contributed...

About ADAC Headquarters

The new headquarters of the German Automobile Club (ADAC) features a dynamic design and harmonized concept, enriching the Munich skyline. With 75,000 square meters of usable space above ground, and 50,000 square meters of usable space below ground, ADAC headquarters offers all 2,400 ADAC Munich staff an abundant amount of room, including offices, a large conference and training center, a restaurant and a printing plant.

The building complex consists of a five-story plinth building, upon which a high-rise tower is constructed. The ground plan of the star-shaped plinth building measures 187 meters in a longitudinal direction and 107 meters in a transverse direction. The ground plan of the high-rise building atop the plinth measures 35 by 65 meters.

The high-rise tower was deliberately placed next to the railway tracks so that it neither cast shadows onto the courtyard and neighboring buildings, nor dominated the street.

A large number of demanding engineering solutions were required to support the high-rise tower, to build above two existing underground railway tunnels and transform the round body of the building above ground into a rectangular basement structure below. The foyer area, spanned by a multifunctional steel-and-glass roof, as well as the complex building façade, which allows individual user control, also proved to be particularly demanding challenges.

The structural system developed for the cantilever of the tower on the north-eastern side of the building provides a good example of an innovative solution. On the side facing northeast, the tower building stretches approximately seven meters beyond the contour of the plinth building. The loads from the columns running along the façade of the high rise had to be transferred to the recessed columns in the base building. For this purpose, the design team developed a system of slanted struts extending over three and five stories, respectively. This solution required engineers to find a balance between tension and compression loads acting on the struts. Compared to space frames and trussed girders, this solution not only uses less space, but can also be constructed at less expense.

The main sustainability strategies begin with the building’s siting over active railway tracks. The necessary 350 deep-bored piles for the foundation were "activated" with plastic pipes to bring up ground water into the floors of the building for thermal cooling and heating. The facade construction prevents infiltration by using relatively simple, low-tech componentry. To provide natural ventilation for all office spaces an economical composite window was developed. The window construction includes a mechanical air supply device with mechanical flow control, which regulates the flow of fresh air and automatically closes under excessive wind pressure. Sun protection blinds, mounted behind the baffle pane of the composite window, minimize the solar gain while optimzing the use of natural daylight.

Inside, the various routes toward the building converge at a central glazed foyer in the courtyard; from here, a “ring road” on the first floor serves as an internal street connecting together the six parts of the building, each with its own service core. Elevating the internal circulation made it possible for the ground floor to be dedicated to public use.

CTBUH Awards & Distinctions

Best Tall Building, by Region, Europe 2013 Award of Excellence

2013 CTBUH Awards

Subscribe below to receive periodic updates from CTBUH on the latest Tall Building and Urban news and CTBUH initiatives, including our monthly newsletter. Fields with a red asterisk (*) next to them are required.

View our privacy policy